I enjoy building and designing motors. It has been a passion in my life for years, and only gets stronger by the day! I REALLY enjoy custom tailoring motors for individual needs, even with off the shelf parts. Over the past few years I have had the pleasure to build motors pulling from a variety of “ideals” on what the best should be, giving motion to regular Joes and the world’s best drivers alike.

John Robert Holmes

—————————————————————————————————————————-

The following page is a listing of motors ranging from off the shelf Custom to machined Prototype. CAD and FEMM analysis and design is used for the housing, magnetic circuit, electromagnetic circuit, stator, rotor, and shaft specifications. PMDC brushless, Brushed, Inductance, Reluctance, and hybrid motors can be built in radial, axial, and 2.5d flux. Although we service the R/C market in higher volumes, robotic and electric vehicle systems are also our specialty.

You can find custom 540 motors available for purchase at http://holmeshobbies.com/product.php?productid=480&cat=0&featured=Y

———-

Team Flow motors for Multi time National USRCCA series champ Austin Dunn. I have hung out and crawled with him for years and knew exactly what he wanted. Big power, smooth control, but not too heavy. We could have gone nuttier in any direction, but sometimes a balance is the best option.

Skewed 3 slot arms, 30t medium fill, epoxy balanced

laydown brushes

Stage 4 Lightening

flux rings for on the spot tuning and emergency torque

Black varnish coating

———-

2012 Team Crawl for overall National Champ “Turbofest”. James wanted light, and was building a super light rig to match. He didn’t want hammer down power as much as lightweight smoothness. Enough oomph to get going fast, but light and super smooth down low.

5 slot CrawlMaster arm, 13t medium fill, epoxy balanced

Standup brushes

Stage 3 lightening

Black oxide coating

———-

2012 Team Flow Missouri Champion “JeepSoHigh” wanted a set of motors that were like a sledgehammer on course, but smooth enough to have great tactile feel down low.

Skewed 3 slot arm, 30t high fill, epoxy balanced

Laydown brushes

Stage 3 kit

Blue hoods

Raw Oiled steel

“light” colors

———-

2013 Team Flow motors for Eddie from Crawler Innovations. He also wanted something like an iron fist on course, but he wanted full torque and then some. Looks were also important, he wanted them looking sharp! Drag brake was a big concern for Eddie, but not startup. We balanced the difference with stronger FB12 magnets and a slightly skewed armature.

Skewed 3 slot arm, high wire fill, epoxy balance

Laydown brushes

Orange hoods

FB12 magnets

“blacked out”

Here was a cool set of motors sent to Japan with heatsinking on the can. They turned out sharp! (not literally)

Another set of Custom Pros, black on black with laydown hoods and “stealth” internals.

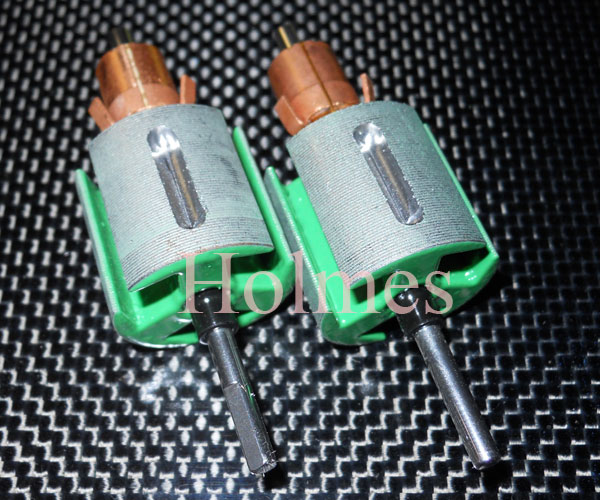

Shown here is a set of vertically slotted armatures for a customer that wanted more low end pop and mid range power. Since this is for a crawler and not a racer we didn’t go nuts removing material. The efficiency and peak torque stays high, we get the throttle feel wanted, and motor startup doesn’t get unusable. A more aggressive and full length vertical slot affects startup speed to the point of being unusable unless we also weaken the magnetic field. Later today these armatures will finish the manufacturing process and be assembled into motors.

The option is available within our easy to build Pro Custom 540 Motor http://holmeshobbies.com/product.php?productid=480&cat=0&featured=Y. There is also angled and horizontal slotting for those that don’t want to worsen startup speed, but still want more power. As compared to a 4mm web armature, an angled or horizontal slotted 5mm web armature has much better startup.

This is a set of motors for a team driver that wanted smooth low end, but big drag brake, torque, and high wheelspeed. We opted for a set of Team Flow motors, built as customs in all black with upgraded magnets. FB12 magnets, 30t high fill wire, 10mm comm, XX springs, silver brushes, and alloy hardware rounded out the build.

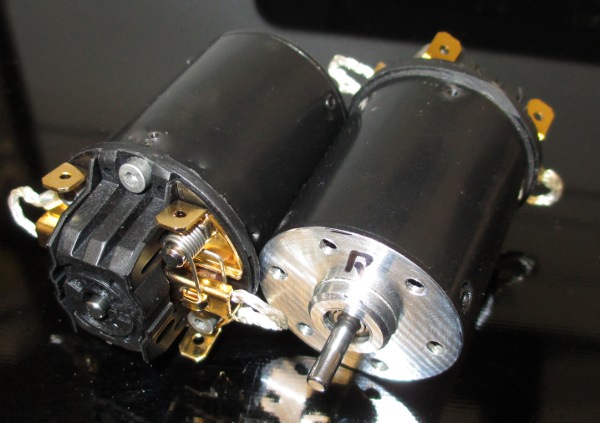

The following set of motors is for multi-time National Champ J. Ripplinger. They are truly a custom set of motors. The endbell is machined and assembled from 540 parts. The can is made from chromoly. The faceplate is machined from aluminum. Setscrews for the can are stainless, and hardware to hold the endbell is 7075 aluminum. I populated the cans with N34 neodymium magnets with a special layout for best startup and low speed resolution. The timing rings are machined from fiberglass. Armatures were custom built for me by Sagami for prototype work. I wound them to just over 2500kv, a very peppy wind that is perfect for Ripplinger’s style of driving. The pair of motors weighs 250 grams on the nose. A full 1/4 pound less than a pair of regular 540s!

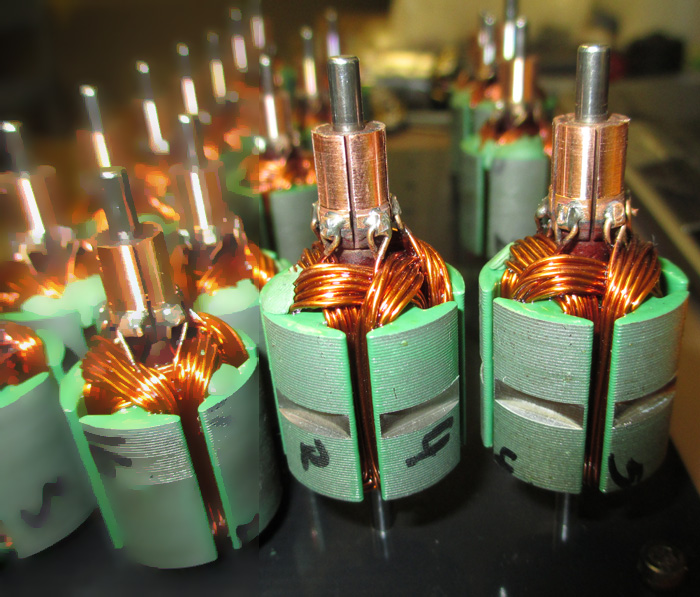

The following are Team Crawl Type arms built for world champion drivers. They are double wire with offset coil termination and kevlar reinforcement. The offset termination allows an extra 33% wire fill increase without lengthening armature.

We use oxygen free copper wire with 200c rated insulation. Wire termination was reinforced with a 650c high silver filler via resistance brazing methods with electrical specific fluxes to prevent copper embrittlement. A 200c rated resin was impregnated into the coils after winding. Then we dynamically balance with the finest German balance epoxy. Standard day at the office!

After we cut the comms they will get assembled into motors and sent out.

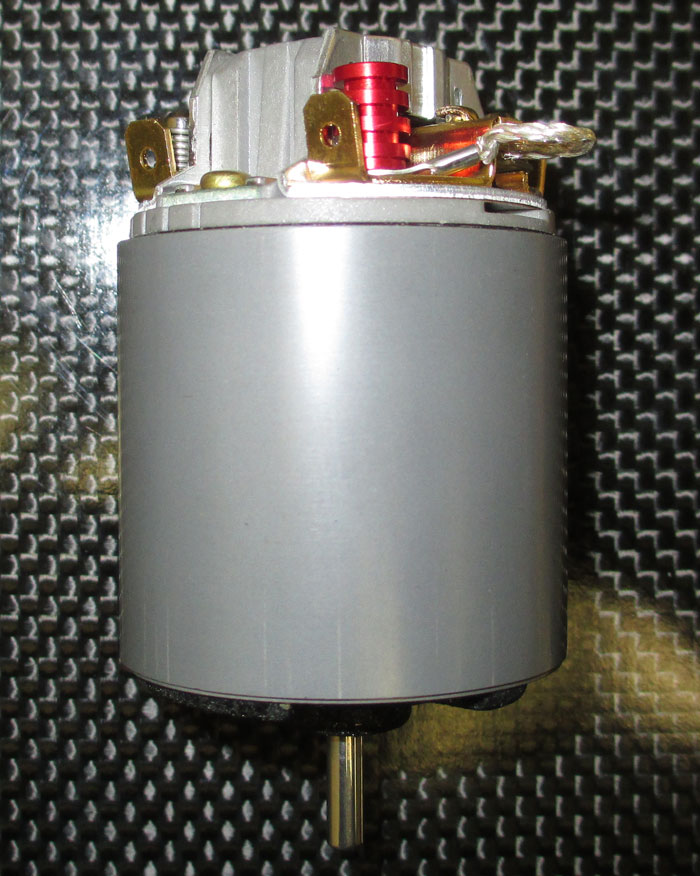

This motor is a custom project for a ballistic weapons company. Compared to a regular 540 it has about 10% more weight, but terminal resistance is less than 1/2 for the equivalent speed. All in the same size package! The pics will show the story. A large rotor and Neodymium magnets are used to maximize torque and power density.

As usual, termination on the commutator was done with high silver content braze filler for the best connection possible.

The next custom rotors were for a customer wanting lighter weight and very smooth power delivery. High power was not a priority. Horizontally slotted 5 slot arms were the choice. The machining reduces airgap flux density slightly, reduces weight, decreases inertial mass, and reduces cog force of the motor.